|

The Clock |

The Clock

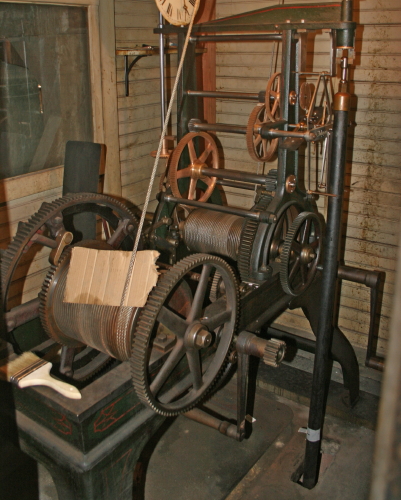

The tower clock is a Nels Johnson Century Clock and one of the finest of it's time. It is unclear why San Jose received such a fine time piece (accurate to a few seconds per month), though speculation is that a precision time piece was needed for the Lick Observatory on Mount Hamilton or early radio broadcasting that started in San Jose. It has also been noted that the United States Weather Bureau was established in San Jose in 1906 and housed on the second floor of the building (then Post Office). Another possible reason for having such a fine clock was that Mr. Johnson was a member of the Astronomical Society of the Pacific and with his associate Professor Hussey of Stanford needed accurate timekeeping calculations for astronomy.  The clock itself is unassuming, with the weights and pendulum mostly hidden. But a closer look reveals an intricate works of gears that keep the clock running smoothly and accurately. The gearing is very robust, and the gear tooth count is very fine. The end result is a very low friction, precision time machine that isn't likely to be exceeded in quality. While Nels Johnson clocks have the heavy look of factory equipment, made as they were, by a machinist more concerned with function than aesthetics. They are of the highest quality. The wheels and pinions were of gunmetal or close-cast iron, with all teeth cut by Brown & Sharpe involute cutters. Toward the end of his life Johnson concluded, "For years I have tried to build a clock that created perfect time, but now I am convinced that only the Creator can do that. The stars in their course through the heavens never vary, but man-made timepieces will ever be fallible. I have made clocks that vary only three or four seconds in a month, but I believe that is the limit." The clock faces sit in a room above the clock driven by a mechanism that comes up from the clock in the center of the room and rotates the three faces. The clock is hand wound a couple times a week by SJ Museum of Art staff. The winding lifts a 600 lb strike weight that drives the clock. Normally, the bell would sit above the faces in a belfry that allows the bells sound to care out from the building. Unfortunately, since the restoration was never completed, the bell sits next to the clock, thoroughly surrounded by thick sandstone brick walls. When rung, the sound is trapped in the tower and goes straight down into the offices below. The bell was made by Andrew Meneely's foundery in West Troy, New York. The Bell is inscribed: Meneely & Co. West Troy, NY 1908 Nels Johnson Sr. Manufacturer of Century Tower Clocks Manistee, Michigan 1908 |

|